Industrial piping networks are the backbone of countless industries, from energy production to chemical processing. They transport gases, liquids, and steam under conditions that often push the boundaries of temperature, pressure, and mechanical stability. Ensuring that these systems remain reliable requires more than just strong materials; it requires a deep understanding of how stress, movement, and thermal expansion affect performance over time.

One of the major challenges engineers face is the natural movement of piping systems. Thermal expansion and contraction occur whenever a material undergoes temperature fluctuations. For example, in a refinery or power station, pipes may experience swings from sub-zero conditions to temperatures exceeding several hundred degrees Celsius. Left unchecked, these movements can stress welds, joints, and fittings to the point of premature failure.

The importance of flexibility in design

When engineers design piping systems, they must strike a balance between rigidity and flexibility. Pipes that are too rigid can crack under stress, while overly flexible systems may lack the structural stability needed to maintain flow and alignment. To address this, designs often incorporate loops, offsets, and other features to absorb mechanical forces without damaging the system.

A related consideration is vibration. Pumps, compressors, and turbines introduce oscillating forces that can cause fatigue failure if not properly accounted for. Adding support structures, vibration dampeners, and flexible sections allows systems to withstand these dynamic conditions. Proper vibration control not only extends the life of the system but also reduces noise and energy loss.

Materials matter

The selection of material plays a central role in system durability. Stainless steel, carbon steel, and specialized alloys are chosen based on their ability to resist corrosion, withstand temperature changes, and maintain mechanical integrity. In some applications, composite materials are being explored for their lightweight properties and resistance to chemical attack. However, metals remain the gold standard in high-pressure and high-heat applications.

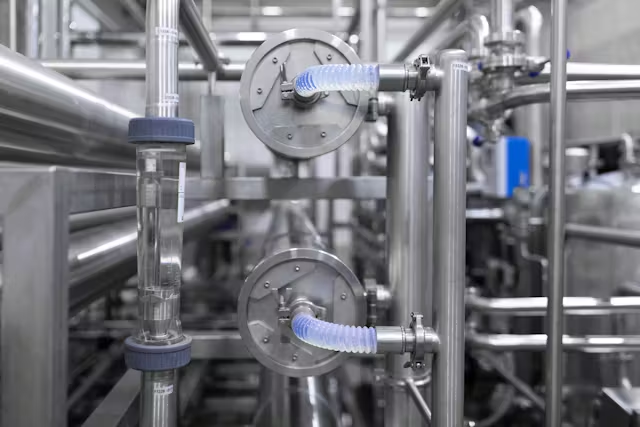

Addressing movement and stress concentration

To manage the inevitable expansion and contraction, engineers often introduce specialized components. For instance, an expansion bellow can be installed to absorb thermal movement while maintaining a sealed system. This component acts as a flexible joint that compensates for stress, preventing cracks and leaks in surrounding sections. By using such solutions strategically, systems can operate more reliably and safely under demanding conditions.

Maintenance and inspection

Even the best-designed systems require ongoing monitoring. Over time, wear and tear can introduce weaknesses. Regular inspections using non-destructive testing methods—such as ultrasonic testing or radiography—help identify thinning walls, micro-cracks, or hidden leaks. These proactive approaches allow teams to repair or replace parts before they fail, avoiding costly downtime and potential safety hazards.

In industries where safety and uptime are paramount, predictive maintenance strategies are gaining traction. By embedding sensors that track temperature, vibration, and strain, companies can gather real-time data on the condition of their piping systems. This predictive insight helps optimize maintenance schedules and reduces the risk of unexpected failures.

Environmental and regulatory considerations

Beyond operational performance, there is increasing pressure on industries to manage environmental risks. A small leak in a petrochemical pipeline can have devastating consequences for ecosystems and communities. Regulators are tightening safety standards, requiring operators to demonstrate not only compliance but also proactive risk management.

Companies are now integrating sustainability goals into their engineering practices. Using longer-lasting materials, reducing emissions, and recycling components are all strategies that align with both regulatory demands and environmental responsibility. As industries transition toward greener operations, the reliability and adaptability of piping systems remain a top priority.

Looking ahead

Technological advancements are reshaping how industries approach piping system management. Artificial intelligence is being used to analyze sensor data, providing early warnings of stress accumulation. Advanced manufacturing techniques, including 3D printing, are allowing for more customized components that better match specific operating conditions.

The ongoing evolution of piping system engineering reflects a broader trend: industries are moving from reactive problem-solving to proactive resilience-building. By focusing on flexibility, material science, and predictive monitoring, companies can ensure that their systems stand the test of time.